NAV:

Item number: NZ010A

Material: Pure cotton fermented and washed

Features: Comfortable, wear-resistant, moisture absorbing and breathable, easy to clean, no pilling, dual track technology.

Season: Spring and Autumn

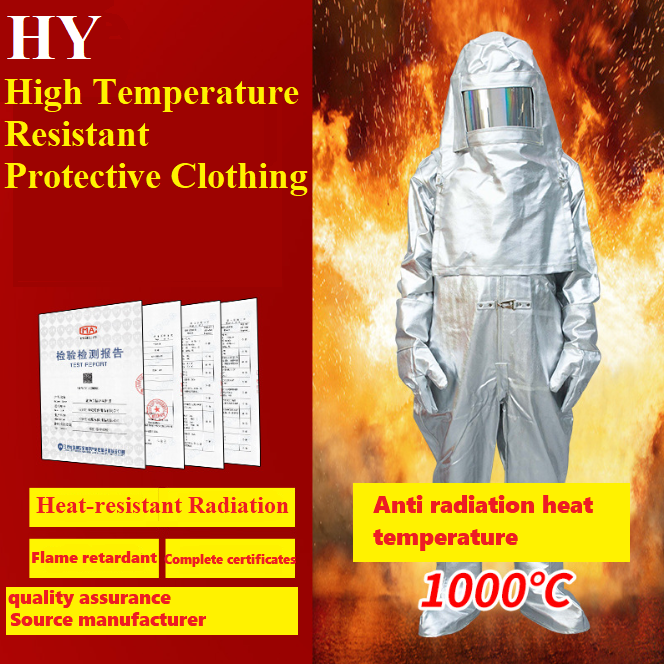

Fire and heat prevention

Welding work clothes need to have fire-resistant and heat-resistant functions to protect welders from high-temperature metals and sparks. Generally speaking, the fabric of welding workwear needs to have high flame retardancy to effectively prevent the spread of flames.

Wear resistant and tear resistant

Welding work clothes need to have good wear resistance and tear resistance to ensure that they are not easily worn or damaged during the work process. This can effectively extend the service life of welding work clothes and reduce safety hazards caused by clothing wear or damage.

Comfortable and breathable

Welding work clothes need to have a certain degree of comfort and breathability to ensure that welders can maintain comfort even in high temperature, high pressure and other environments. Generally speaking, the fabric of welding workwear needs to have a certain degree of breathability to allow the welder's body heat and sweat to dissipate, while keeping it dry and comfortable.

Key attributes

Industry-specific attributes

Age Group :Adults

Printing Methods :Embossed, Heat-transfer Printing

Material :Denim

Other attributes

Place of Origin :Hebei, China

Supply Type :OEM service

Gender :Unisex

7 days sample order lead time :Support

Seamless Fusing: NO

Brand Name :Haiyuan, HaiYuanYiShang/HengLu

Model Number: NZ010A

Product Name: Workerwear Uniform

Size :s-4xl/Customised

Function/Feature :soft/breathable/wear-resisting

Brand Name :HaiYuanYiShang/HengLu

Port :TianJin

Place Of Origin :ShiJiaZhuang,HeBei,China

Age Group :Adults

Material: Denim

Logo :Customer's Logo

Service :OEMservice

Packaging and delivery

Selling Units: Single item

Single package size: 40X30X6 cm

Single gross weight: 1.500 kg

1. Personal protection

When carrying out metal welding and cutting operations, workers must wear appropriate protective equipment, including dust masks, welding gloves, and specialized welding work clothes. Eye and facial protection is particularly important, and goggles or face shields should be used. When working in humid environments or rainy days, rubber shoes should be worn. In special circumstances, a long tube respirator can be worn to prevent smoke and dust hazards. Choose filter lenses suitable for current intensity to prevent arc damage, and wear light colored canvas work clothes to reduce skin damage.

2. Pre work inspection and cleaning

Before operating any container, pipeline or workpiece, it is necessary to thoroughly inspect and clean all toxic, flammable and explosive substances, and ensure that the container and pipeline are pressure free and non sealed. Before hot work, it is necessary to sample and analyze the substances inside the container to ensure compliance. When welding or cutting closed hollow workpieces, it is necessary to ensure that there are air holes retained. When working inside containers, there should be a dedicated person to supervise and ensure good ventilation and lighting.

3. On site safety

To prevent fire and explosion accidents, the workplace should be inspected before work to ensure that there are no flammable or explosive materials. During gas welding or gas cutting operations, it is necessary to check whether there is any air leakage in the bottle valve, pressure reducing valve, and rubber hose. During welding operations, attention should be paid to the possibility of fire caused by excessive current and wire problems. Before and after homework, check the equipment to prevent heat conduction from causing flammable and explosive materials on the other side to catch fire or explode. Effective firefighting equipment should be equipped at the work site.

4. Preventing electric shock accidents

The casing and metal components of the welding machine must be grounded (or zeroed) to ensure sufficient insulation resistance. During operation, a safe distance should be maintained between the charged body and other objects. When welding at heights, avoid contact with high-voltage power grids and do not wrap cables around your body. When moving, repairing welding machines, or replacing fuses, the power must be cut off. When an electric shock accident occurs, immediately cut off the power and provide first aid.

5. Other measures

Ensure good ventilation in the workplace and use welding materials with minimal impact on occupational health. Personnel engaged in welding operations for a long time should undergo regular health examinations and adjust their job positions in a timely manner to prevent occupational diseases.

As a leading manufacturer of workwear and protective equipment in China. Our company can provide customers with different types of Workwear. You can choose styles directly from our website. In addition, if you have customized style design drawings, we can provide OEM service for you.

Back to Top

+8619948039507