Project Number: TZ2068

Color: Green

Season: Spring and Autumn

Fabric: Aramid fiber fabric, non pilling, non fading, durable and wear-resistant, soft and comfortable.

Features: Thermal insulation, heat resistance, wear resistance and durability

Gender: Men and women with the same style

Size: S/160, M/165,L/170,XL/175,2XL/180,3XL/185,4XL/190,5XL/195

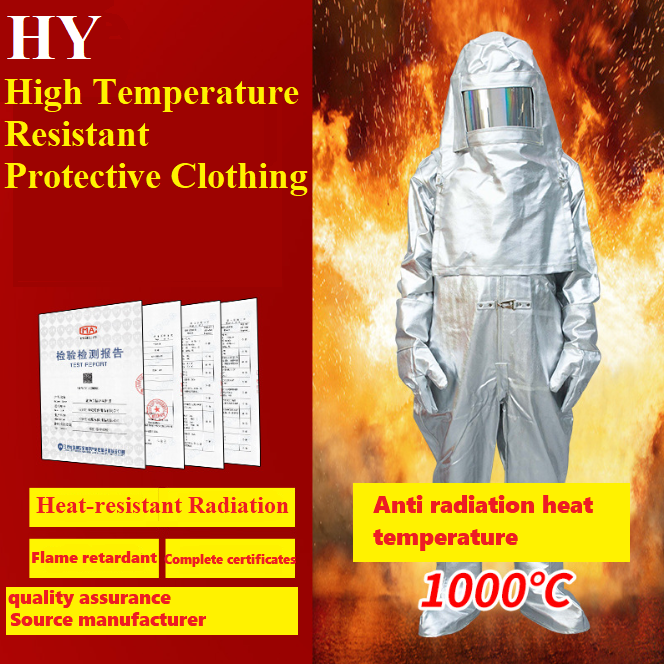

Technology: After being treated with flame retardant technology, it does not burn, melt, or spark when exposed to open flames. It has good flame retardancy, environmental protection, washability, comfort, breathability, easy washing, and durability. The entire process fabric is stylish and comfortable.

Is there a test report: Yes

Supply type: Supports OEM services

Logo: Supports logo customization

7-day sample order delivery cycle: supported

Key attributes

Industry-specific attributes

Age Group:Adults

Printing Methods:Embossed, Heat-transfer Printing

Material:Aramid fiber

Other attributes

Place of Origin:Hebei, China

Supply Type:OEM service

Gender:Unisex

7 days sample order lead time:Support

Seamless Fusing:NO

Brand Name:HAIYUAN

Model Number:TZ2068

Product Type:Flame Resistant Shirt

Application:Factory

Style:Work Uniform

Color:Green

Logo:Customers' Logo

Function:Flame Resisitant

Description:Working Coveralls Safety Workwear Uniforms

Season:Spring Autumn

Sample time:5-7 Days

Certificate:ISO9001

Packaging and delivery

Selling Units:Single item

Single package size:50X48X7 cm

Single gross weight:1.950 kg

Aramid flame retardant fabric is a new type of high-tech synthetic fiber. Aramid flame retardant fabric has excellent properties such as ultra-high strength, high modulus, high temperature resistance, acid and alkali resistance, light weight, insulation, aging resistance, long life cycle, etc; Aramid flame retardant fabrics are widely used in composite materials, bulletproof products, building materials, special protective clothing, electronic equipment and other fields.

1. Aramid flame retardant fabric

The main component of aramid flame retardant fabric is aramid fiber, also known as aromatic polyamide fiber. Aramid fibers include meta aramid and para aramid. The commonly used aramid flame retardant fabric for flame retardant protective clothing in the market is commonly referred to as 93/5/2 fabric. Its fiber composition is 93% meta aramid, 5% para aramid, and 2% conductive fiber, which was first developed by DuPont. In addition, there are also aramid flame retardant fabrics developed with different ratios to meet different needs.

2. Flame retardant mechanism of aramid flame retardant fabric

The main component of aramid flame retardant fabric is aramid fiber, especially meta aramid. The molecular structure of aramid fibers is arranged in a regular zigzag pattern, which decomposes before melting. The glass transition temperature is around 270 ℃, and no significant decomposition or carbonization occurs below 350 ℃. When the temperature exceeds 400 ℃, the fibers will gradually become brittle, carbonized until decomposition, but will not produce droplets, and have good flame retardancy, with a limit oxygen index of 28% to 33%. In addition, aramid fibers also have the characteristics of high strength and high modulus. Therefore, aramid flame retardant fabrics are widely used in military, police, firefighting, and industrial protection fields. Especially when high durability is required for fabrics, aramid flame retardant fabrics are one of the good choices.

3. Differences between aramid flame retardant fabric and cotton flame retardant fabric

The two best-selling flame retardant fabrics on the market currently are aramid flame retardant fabric and all cotton flame retardant fabric. The price of aramid fabric is more than five times higher than that of all cotton flame retardant fabric. Because aramid flame retardant fabric belongs to fiber flame retardant, it is a natural flame retardant fiber that does not require post flame retardant finishing. The fabric has a soft touch, strong strength, good flame retardant performance, and high temperature resistance. Especially when exposed to high temperatures of 900-1500 ℃, the fabric surface will quickly carbonize and thicken; However, all cotton flame-retardant fabric belongs to the category of post processed flame-retardant fabric. The material itself does not have flame-retardant properties and needs to undergo flame-retardant treatment to have flame-retardant performance. The physical and flame-retardant properties of all cotton flame-retardant fabric are not as good as those of aramid flame-retardant fabric.

The maintenance of aramid flame retardant clothing mainly includes the following aspects:

Cleaning and maintenance: Special attention should be paid to aramid flame retardant clothing during cleaning. It is recommended to use neutral soap or enzyme free detergent, and the water temperature should not exceed 40 ℃. After washing, dehydration treatment should be avoided. Instead, choose to air dry naturally or iron at a high temperature of 150 ℃ for 2 minutes to ensure that the flame retardant effect is not affected.

Inspection and repair: After each use, check the condition of the flame retardant clothing, remove residual dirt, especially oil stains and chemicals, and avoid using acidic detergents. If there are slight wear or burn marks on the surface, an aluminum plating spray gun can be used for repair, and severely damaged parts need to be replaced.

Storage and protection: Flame retardant clothing should be completely dry before storage to avoid mechanical or chemical damage. When storing, it should be placed in a dry and ventilated place, avoiding direct sunlight exposure to extend its service life.

As a leading manufacturer of workwear and protective equipment in China. Our company can provide customers with different types of Workwear. You can choose styles directly from our website. In addition, if you have customized style design drawings, we can provide OEM service for you.

Back to Top

+8619948039507